Biological Service

Benefit from more than 20 years of experience and the specialist knowledge of our scientific staff. You can choose between different levels of support. Whether you opt for initial biological advice, a consultation on process disruptions or complete support through “Fit for Biogas”, our specialists are always there for you.

Our laboratory is:

- Accredited* in accordance with DIN EN ISO/IEC 17025:2018

- Notified and approved for analytics and sampling

- Approved in accordance with the German Federal Compost Association

* Only applies to the test procedures listed in the accreditation certificate.

Standards in flexible scope

Download PDF

Biogas analytics

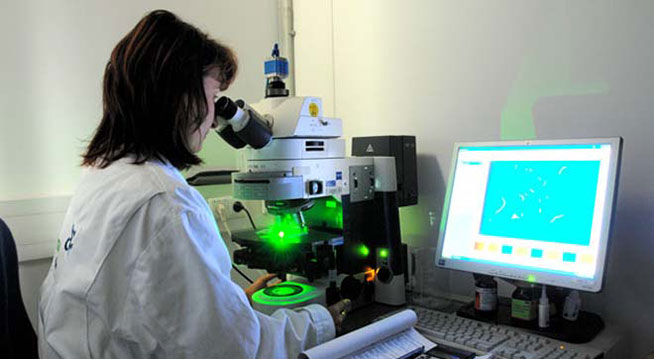

Our accredited in-house laboratory offers a comprehensive analytics package for biogas plants: from the evaluation of different feedstocks to fermentation process control and assessment of the fermentation residue. State of the art analytical equipment and specially developed analysis methods provide reliable and rapid results.

Insight into the digester

In addition to safe and reliable plant technology, a stable fermentation process is an essential factor in the profitability of your biogas plant. For the process to run optimally, it must be monitored regularly and optimised as necessary. Our comprehensive biogas analytics provide reliable and comprehensive results from all important process variables in the ongoing fermentation process. From the analysis of feedstocks to process monitoring and fermentation residue assessment, we offer you the best foundation for safe and reliable biogas production.

Take advantage of these benefits:

- Maximum stability in the fermentation process

- Profitable operation

- Sustainable process control

- Fermentation process monitoring

Our services in detail:

- Feedstock analytics

– Batch fermentation test (VDI 4630)

– NIR gas yield

– Dry matter and organic dry matter - Process analytics

– Fatty acid spectrum

– Macro and micro substances

– Inhibitors, etc. - Fermentation residue analytics

– Nutrient examination

– Pollutant examination

– Residual gas potential, etc.

Environmental analytics

Safety for people and the environment

Plant operation is subject to various laws and regulations to ensure safe operation for people and the environment. To ensure that your plant satisfies these requirements, we determine precise values using recognised high quality measuring methods.

We work with tried and tested analysis techniques and provide reliable support in the interpretation of your specific results.

In environmental analytics, we monitor all parameters regarding biowaste, fermentation product, compost, sewage sludge and water.

Take advantage of these benefits:

- Protection for people and the environment

- Sustainable quality assurance

- Compliance with regulations, directives and laws

- Reliable plant operation

Our services in detail:

- Analytics in accordance with the German Fertilisers Regulation (DüMV)

- Analytics in accordance with the German Ordinance on Biowastes (BioAbfV)

- Analytics in accordance with the German Sewage Sludge Ordinance (AbfKlärV)

- Analytics in accordance with the German Federal Compost Association

- Waste water analytics

Biological support

We do all we can to ensure that the biology of your plant is just right. As part of our biological consultancy, our laboratory will carry out precise analyses of the biological process of your plant. Using these results, we can develop specific recommendations and suggestions on how you can stabilise and increase the performance of your plant.

Biological commissioning – A successful start

The first biological commissioning measures will begin before construction work is complete. Our experts will support you over a fixed period of time.

The first step is to test the start-up materials and substrates. A detailed catalogue of measures will then be developed, including filling your plant, the quantity and mixing ratios, as well as charging of your plant.

During commissioning, the fermentation process is continuously monitored by means of regular laboratory analyses. This allows us to assess the current situation and advise you on all further steps. You will receive a detailed report showing all results from the monitoring period as well as information and recommendations on the further operation of your plant.

This supported start to biogas production ensures that you have a stable and resilient basis for plant operation.

Take advantage of these benefits:

- Continuous monitoring of the commissioning process

- Interpretation of analysis results

- Feed recommendation

- Advice based on experience from over 60,000 process analyses

- Detailed documentation

Fit for Biogas

Individual advice on biological issues

“Fit for Biogas” is the safe and easy way to identify the continuous changes and requirements in digester biology. Our analyses and recommendations will help you to implement the measures needed to secure and optimise the yield from your plant.

With a Fit for Biogas contract, you can receive sound, tailored advice on your process biology whenever you need it. In addition, we take care of the complete documentation, in accordance with the requirements of the respective grid operator.

Take advantage of these benefits:

- Stabilisation of the process biology

- High plant capacity utilisation

- Understanding of digester biology

- Seamless documentation of the fermentation process

Advice in the event of process disruption

Rapid and reliable assistance

Process disruptions in the plant biology, such as process inhibition, overfeeding or signs of deficiency, can be annoying and reduce plant capacity utilisation.

We provide rapid, flexible assistance to ensure that process disruptions are fixed as quickly as possible. Our contractors get results quickly and reliably, and can provide comprehensive advice on plant-specific issues. Get in touch with us as soon as possible so that we can get your plant back to normal operation without delay.

Take advantage of these benefits:

- Short response times

- Rapid analysis results

- Comprehensive advice

Optimisation package

Improve the efficiency of your biogas plant

Do you know how much potential your biogas plant has for biological optimisation? With the aid of operating data such as substrate types and quantities, feedback, operating resources, gas/electricity production or gas quality, we can prepare a situational analysis of the current state of your digester biology. This will give you detailed information on your plant biology and show us the areas in which your plant can be optimised.

With this data, we draw up clear recommendations for action to help improve performance immediately. This could be a charging adjustment or amending the quantity of operating resources required. It will allow you to get more out of your plant without the need to make structural changes.

Take advantage of these benefits:

- Increase in plant efficiency

- High stability of the fermentation process

- Maximum plant availability

Equipment

Your biogas plant on laboratory scale

To test new feedstocks, we ferment substrates and waste in our in-house technology centre and test their suitability as biogas substrates. This requires the biogas plants in the technology centre to be continuously operated and analytically monitored and the fermenting microorganisms to be examined in the biological laboratory. Our technology centre captures all reliable and practical data for you, which can be transferred directly to your biogas plant.

Our services in detail:

- Continuous wet fermentation of different substrates

- Optimisation of the operating method of biogas plants and waste plants

- Declarations on biological and technical load limits

- Microbiological process analysis

- Recognition of inhibitory effects

- Flexible gas production through flexible feeding (improved flexibility, demand-driven feeding)

METHANOS® F³

Increase plant performance without modifications to the digester

Adding METHANOS® F³ to your biogas plant allows the biogas process to be controlled and optimised in a more targeted way. It yields a significant increase in the efficiency of the biogas plant without the need to make major changes to the technical setup.

Substitution of feedstocks

Adding METHANOS® F³ allows you to replace conventional feedstocks such as maize and whole crop silage with less readily degradable substrates, such as grass and solid manure. This results in lower feedstock costs.

Take advantage of these benefits:

- Increase in specific gas yield

- Optimisation of substrate utilisation by improving the degradation level

- Significant increase in space capacity utilisation without increasing the active digester volume

- Reduced running costs with concurrent increase in yield

- Change to substrate mixture possible

novoDYN®

Why trace elements?

Microorganisms produce enzymes to split up biomass. Microorganisms need trace elements for enzyme production and for their own metabolic processes. These need to be fed into the digester continuously.

novoDYN® for every substrate mixture

In extensive trial series by our accredited in-house laboratory, we have been able to determine the ideal ratio of the individual trace elements in the fermentation process, independent of the feedstock. novoDYN® is the key to needs-based supplementation of the trace element content in the digester and can be dosed flexibly according to the substrate used.

Take advantage of these benefits:

- Increase in plant capacity utilisation

- Stabilisation of process biology

- Increase in substrate degradation performance

- No hazardous substances

- No water hazard class

Trace elements – pure salts

Essential trace elements for process optimisation

Signs of deficiency cause the biological process to slow down. Existing organic substances are not converted into biogas optimally or completely. Substrate changes in particular increase the specific demand for certain chemical components.

Achieve a noticeable improvement to your process biology with specific charging of these missing trace elements through pure salts.

We can also support you with a slide gate (compliant with TRGS 529) for zero-emissions supply of salts and operating resources.

Iron preparations

Reduction in sulphur loads

Sulphur is formed when your plant is charged with almost all the substrate types available. Protein-rich substances in particular contribute to a high hydrogen sulphide content. High sulphur loads in the biogas can cause major damage to the plant technology, e.g. to the CHP unit.

The addition of iron preparations to your digester binds surplus sulphur, preventing it from entering the gas phase. Additionally, it also helps to improve availability of the trace elements for your microorganisms and supports their enzyme formation at the same time.

Take advantage of these benefits:

- Optimisation of the gas composition

- No damage to plant components

- Available in liquid and solid form, depending on the plant configuration

Rockaway struvite protective agent

Preventive protective agent for the continuous reduction and prevention of hard deposits

Deposit formation

Under certain conditions, crystallisation can occur during operation of biogas plants, leading to problems with deposits in pipelines carrying percolate. Changes in temperature and pH value in particular can lead to deposit formation. Deposit formation is especially commonplace in heat exchangers, pumps, nozzles and other outlet openings, pipelines and filter systems. Deposits cause operating faults and plant downtime, leading to additional cleaning and maintenance.

Preventing deposits

The solution is chemical in nature, in the form of crystallisation inhibitors. The struvite protective agent is a modified phosphonate and polycarboxylic acid combination that effectively prevents deposits.

Take advantage of these benefits:

- Low investment costs

- Easy and fast installation

- Increased operational reliability thanks to undiminished flow rate and throughput of the pipelines

- Higher availability of the plant

- Simple control

- Universal use

- Tried and tested in dry fermentation